Winemaking 101

/Harvest can be done either by machine or by hand. Most vineyards in the Langhe and Monferrato areas because of the steep hills tend to harvest by hand. While in some flatter vineyards for the use of Moscato there has been some experimenting going on with machine harvesters. So far the results are quite good.

Once the grapes arrive into the cellar you have a few options:

to de-stem or not

the amount of sulfur dioxide to use

De stemming

In the Langhe there are very few producers who will not de-stem. This is because of a few reasons, the stems of Nebbiolo if not ripe give off a very bitter green tannin which is unpleasant to the wine. Only if you leave the stems to ripen (when the wood changes color from green to brown) then the tannins will be sweeter. In order to do that, you will need to let the grapes hang longer on the vines or in some cases will have a temperature controlled room to store the harvested grapes until the stems are completely ripe.

With that said most producers will de stem their grapes. Most will use a machine that will take off the stems, but since the Nebbiolo berries are more attached to the stems than the other varieties, you will wind up with some bits and pieces of stems during fermentation.

On the other hand there are a few producers who take the berries off by hand. One in the area who started to work in this method was Silvia Altare from Elio Altare, today there are more and more producers working in this way for some of their higher end Barolo’s.

To Sulphur or not to Sulphur

As winemaking trends change there has been much discussion about adding sulfites to wine and when or not at all. The advantages in addition of sulphur to Nebbiolo grapes are:

antiseptic - by adding sulphur to the grape must this will protect against bad yeasts on the grape skins and protect against acetobacter (vinegar bacteria).

antioxidant - to help control oxidation within the wine.

If you do not add sulphur before the alcoholic fermentation starts, typically the producer is then going to have an indigenous yeast fermentation and would want more oxygen in contact with the must to promote growth of the native yeasts.

Alcoholic Fermentation

After you have crushed, now you are ready to ferment. Depending on your winemaking choices some producers use selected yeasts* or indigenous yeats found on the skins. If this is your selected method many producers will make a starter culture (pied di cuve) to help have a strong population of yeasts to start the fermentation.

*With selected yeasts, these could be ones that have been selected from the wineries vineyard and is special to the house or they can chose and active dry yeast that they like. By selecting the yeasts they are stronger and will not have trouble to finish the fermentation when alcohol levels arrive above 4% ABV.

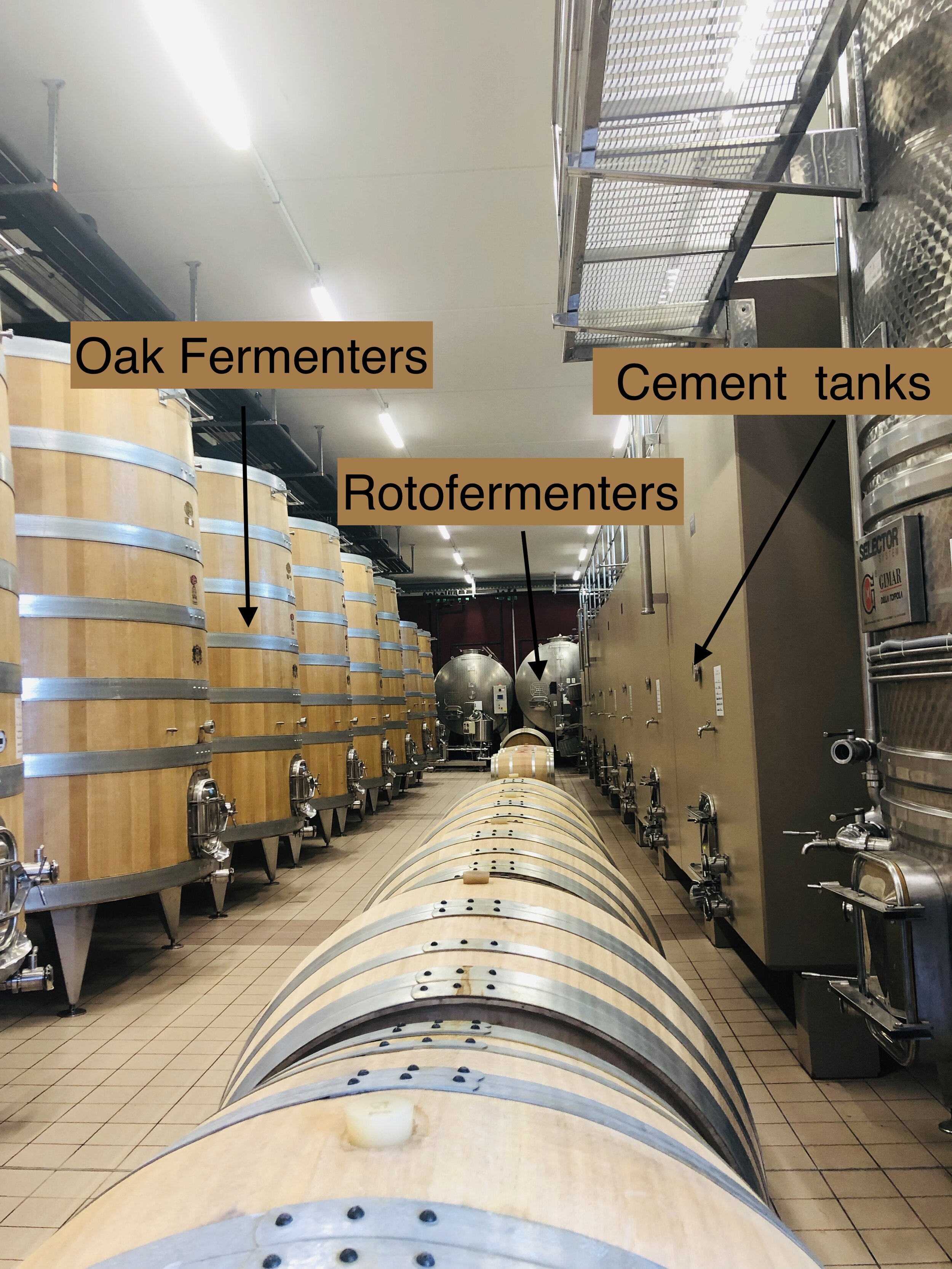

Fermentation Vessels

Here you have a choice:

Tine (large oak upright fermenters)

Cement tanks

Stainless steel tanks

Roto - fermenters

Tine (oak fermenters) are the oldest method and the most traditional in the Langhe area. These large upright oak tanks are a great container to have a smooth fermentation, as it is very uncommon for there to be problems with temperatures going too high in the wooden containers. There is plenty of oxygenation and the musts and wine are fermenting in a natural container. The only downside to the Tine is the cleanliness, but this should not be a problem today.

Cement tanks came into the Langhe area in the 1960’s as cement was easy to install and cheaper than having to buy Tine or Stainless steel tanks. The cement tanks are covered with a glass resin glaze that will make it safe for the wines to undergo the fermentation or aging in these tanks. Cement being quite thermal and heavy is very hard to change the temperature quickly, so these tanks are still used today as they are quite therapeutic for the wine.

Stainless steel came into the Langhe in the 1990’s when there was a revolution in the area going on. More about that here. Before the 1990’s steel was very expensive and the average farmer could not afford it. With the new wave of young producers searching for cleanliness and quality they brought in the use of steel. If the tanks are not equipped with temperature control, fermentation can get a bit out of control with temperature making it harder to cool it down. These tanks are very easy to clean.

Roto-fermenters are a stainless steel tank with paddles built into the center of these horizontal fermenters. This design was invented in the Langhe in the 1990’s by the youngster who revolutionized the area. This invention works quite well for the Nebbiolo grape to extract the color and tannin quite quickly from the skins. With the inner paddles that move slowly (depending also on the speed the winemaker wishes) it is typical for one full rotation every 24 hours. By constantly moving the must the winemaker is able to extract more color from the skins.

After the Fermentation:

The winemaker has two choices:

To remove the skins

Have an extended maceration

If the winemaker decides to remove the skins, the wine will go on to the next part of this post.

If the winemaker decides to have an extended maceration this can be extended as long as the winemaker feels it should. Typically when they are extending the maceration time for another 20-60 days they will submerge the cap into the middle of the tank so it will stay wet and be free of bacteria formations. The winemaker will then decide if they would like to continue with pumpovers or not, and for how many times a day and how long. By doing this they are able to have a maximum extraction of tannin complexity and color.

Malolactic fermentation aka second fermentation

The Malolactic fermentation is a natural chemical occurrence and every wine will go through this step unless it has been chosen not to, and from there will need to have a fine filtration to take out the micro bacteria that performs this transition.

Basically the Malic acid (the acid in a green apple) gets eaten by good bacteria that changes the malic acid into lactic acid (the acid in milk). From this in white wine you will have a buttery mouthfeel or in red wine you will feel a softer smoother acidity. Still mouthwatering.

Oak aging

In the Langhe you have a few options of how to oak age your wines

Botti Grandi (large oak casks)

Barrique (small 250 L French oak barrels)

Tonneaux (medium 500 - 700 L French oak barrels)

The large oak casks are typical from the Langhe area. It is most common to find them from 1,000 L to 10,000 Liter and were used for centuries to make the famous Barolo and Barbaresco wines. These barrels can be used for decades if kept in good condition when cleaned regularly and restored every so many years. It is typical for these barrels to be made out of Slovonian, Austrian, or Hungarian oak. It is very seldom to find them made from French oak. With these large casks they tend to impair less wood flavors to the wines and helps with a steady and low oxygenation.

Barrique and Tonneaux barrels are something a bit new to the Langhe area. They were introduced in the 1980-1990’s when the “Barolo Boys” first started to experiment with these smaller barrels. Barrique and Tonneausx are made from French oak and can have a range of different toasts to the inside of the barrel. By toasting the barrel helps to shape the staves, but a heavy toast can leave more notes of Vanilla and spice in the wine that some people might not appreciate as it can tend to cover up the flavors of the grapes. With all kinds of experimentation happening with these new small barrels there has been an understanding to utilize different ages of the barrels in order to maintain balance within the wine.

If you would like more information about cooperages please check out my post on my visit to Gamba Botti.

After the oak aging the wine will be placed into stainless steel or cement tanks for a period of time in order to settle any deposits left in the wine before being bottled.